Packaging sector conveys a love for innovation

23 June 2010Keeping the production line running smoothly is key to efficient packaging operations, and innovations in conveying systems are helping companies to do just that, reports Emma Jackson.

A packaging system is only as strong as its conveyors, and they can come in all shapes, sizes and specifications. Indeed, countless types of conveyors exist to support every kind of application, yet in the past year – facing challenging economics - companies have been adding even more to the line-up, improving on old ideas and creating completely new ones.

In February of this year, UK-based Dorner Manufacturing released a small conveyor with big benefits: the iDrive conveyor. This packs a lot of punch while taking up very little space, which is particularly useful for small product packaging applications where space is limited.

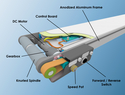

“It’s ground-breaking because it has the motor inside the frame as opposed to outside the frame,” explained Tom Murphy, Director of Automated Suppliers, which is Dorner’s exclusive UK distributor.

According to Dorner, ‘iDrive is an exciting advancement in conveyor technology that merges the very latest drive and control systems with the compact design of the Dorner 2200 Series. By integrating the motor, gearbox and motor controller into a single, space-saving package, Dorner has literally redefined the application footprint for small product conveyors.’

The conveyor can be as narrow as only 75mm if needed, with lengths of up to 3,600mm. And according to Dorner COO Rich Ryan, it is also capable of moving items up to 100ft/min with a load capacity up to 30lb. The conveyor is reversible as well, giving more flexibility. Although it is neither the first nor the only product driven by a DC motor: ‘Only the iDrive conveyors can offer this unique mix of space saving, versatility, speed, strength and competitive price,’ according to the company.

Siemens is also focusing on motor improvements to get ahead. In April, Siemens released its new ‘worm geared’ motors for conveyor systems, which feature high efficiency, extensive transmission range, and a maintenance-free lifespan. According to the Siemens drive technologies division, ‘The use of high grade materials, such as a substantial nickel proportion in the bronze worm gears, allows high rated gear torques up to 80Nm and high transmission ratios of up to 100 in a single stage’.

Another German company, Schüco International, has also been improving its conveyor options, and has recently added the Conveyor Systems Flexible Line (CS FL) made entirely of plastics and designed especially for large widths to transport boxes and cartons. According to the company, the conveyor omits traditional connecting pins on the chain links, but due to the chain’s unique design, which allowso ptimum fit on horizontal curves, the plastics conveyor is as stable and durable as a steel-reinforced chain. A small turning radius allows for tight curves, the company adds, which gives more flexibility when working in a tight space.

Montech has unveiled its new multi-track conveyor specifically for transporting cumbersome and heavy items such as packed boxes and cartons. The conveyor features the option of toothed or untoothed belts, which can carry cartons up to 100kg, and is available with three different drives via the spur gear motor. Montech has also revamped its signature Montrac system,which is typically used to transport parts and products around a plant. At Automatica, however, Montrac’s gentle side came out for the first time as it demonstrated how its smooth ride can successfully and carefully convey fragile materials such as glass beverage bottles.

Accessories

Meanwhile, innovation is not just helping to revamp conveyors themselves - accessories along the system are also making headway. France-based company Savoye Logistics recently released the e-Jivaro – the miniature cousin of its original Jivaro machine. Both are designed to reduce packaging material on the line to help cut costs and waste for businesses, and the e-Jivaro was created especially for companies operating over the internet.

Basically, the Jivaro or e-Jivaro are set up on a conveyor as one of the last packing steps. The conveyor moves a filled (or half-filled) packing carton into the machine, where the box is analysed and cut down to just above the product - reducing void fill and making the packed boxes as small as possible. According to Savoye’s Martin Elliott, this allows more cartons to fit into a truck and therefore reduces harmful emissions.

“If there’s more volume within a vehicle, there’s more reduction of environmental impact,” he explains, adding that ‘the green issue’ is a huge factor for businesses, manufacturers and consumers alike.

The only difference between the Jivaro and the e-Jivaro is that the latter is meant to handle smaller orders, particularly where consumers are purchasing one or two items from an internet store.

Savoye also provides packing solutions, so along with the machines it has tried to help clients to restructure their packing processes, to redesign the boxes so there is less board being cut away - and update their conveying and packing machinery to fit the new packaging materials.

“Instead of having one-size boxes, maybe we use the same footprint but many different heights,” Mr Elliott says. “Because otherwise where are the savings?”

And government-funded research is making change in the industry, too. A group of EU-funded researchers, including academics from some of Europe’s top research institutions, have been looking at optimising packing and conveying systems, through a three-year project called Net-WMS (Towards integrating virtual reality and optimisation techniques in a new generation of networked businesses in warehouse management systems under constraints). The €2.32 million project has applied ‘mathematics, computer systems and modern logistics’ to the age-old conveying problems that have frustrated manufacturers for decades - from unusually shaped items to overweight products - creating new methods to solve unique packing problems quickly and efficiently.

Some of these methods include the creation of algorithms that use a ‘constraint programming approach’ to analyse a packing job’s unique spatial constraints and the possible solutions to them. Also, the team has developed an entirely new computer language for describing packing constraints, such as a container’s maximum weight or the stability level of a pallet, which means manufacturers can be as specific as possible when telling the computer what they need. The system also includes a virtual reality model to help visualise the entire process. All of these tools are interconnected as a complete software system that has the ability to model, simulate and optimise individual packing processes, saving time, money and frustration for the producer. And what’s more, the system doesn’t have to break the bank.

“We decided to focus our attention in the area of spatial optimisation because there was an obvious commercial opportunity,” explains Dr François Fages, the project’s scientific co-ordinator. “Many firms cannot afford expensive software, but even small improvements in the way they pack shipping pallets or use warehouse space, for example, can make an enormous difference to their profitability and competitiveness.”

Indeed, one French company has already reported good initial results, improving its packing process by 5 to 15%. The research team said this may not sound like much, but that eliminating one or two pallets a day can really add up over a year.

The new iDrive conveyor from Dorner Manufacturing features a compact design with the motors, gears and controls inside the frame to save space and add flexibility. IDrive The Jivaro and e-Jivaro are part of a larger packaging conveyor system meant to cut down on packaging materials, increase efficiency and reduce emissions. Jivaro The new compact iDrive conveyor from Dorner Manufacturing was released in February this year. IDrive 2