Packed full of messages

1 September 2007What lies behind the science and technology of sensors and what do retailers and consumers think about “show and tell” data loggers that reveal the inside story of everyday packaged goods. Jo Hunter investigates

Big-budget research is giving a massive push to the development in Europe of “show and tell” communicative technologies such as sensors, two-dimensional barcodes and radio frequency identification tags for fibre-based packaging products. The SustainPack project has been hailed “the biggest and most important packaging research project to ever be undertaken”. One of its missions is to make Europe a global leader in sustainable one- and two-way communicative packaging (CP). SustainPack is also focusing on nanotechnology to add new functional properties to natural-fibre materials. By creating conditions for a swathe of innovative new technologies it is hoped that fibre-based packaging will become “the dominant player in the packaging area within a decade”.

A four-year mammoth task comes to end in June 2008. Around half of its €36m budget is drawn from the European Union’s Sixth Framework Research Programme and the consortium of 35 partners representing packaging research associations, industries and academia of 13 countries.

Fibre-based packaging has a renewable, recyclable and degradable basic raw material but needs to build its role in sustainable supply chains by becoming ever more functional and improving its economic performance. SustainPack project goals include making paper perform better with minimum fibres, built-in barrier properties and new active and interactive features, plus other technological paths to innovative structural design.

Dedicated units are working on renewable composite films incorporating fibre materials and renewable plastics able to compete with synthetic polymers. They are conducting research on cellulose- and mineral-based nanostructures and producing coatings and organic printing inks which will not disrupt paper-recycling processes.

Communicative packaging (CP) is one of six SustainPack sub-projects each of which has set out prove the technical and commercial viability of new technologies. Part of its work is to determine market needs – and society’s wants – in relation to sensor and RFID systems. But a gap has emerged between the technological possibilities and what retailers and consumers really want from packaging.

With 12 months still to run, SustainPack recently held a mid-term news round-up at Wageningen in the Netherlands. Among the headlines was that the economic benefit of sensors to monitor temperature and relative humidity (RH) in the distribution chain of perishable foods has been proved.

“Due to food waste reduction potential, it (sensor technology) is seen definitely to have an important role in the transport of vegetables as an environmentally friendly application of communicative packaging,” said Fatima Kreft, packaging technology scientist at Wageningen Institute’s agrotechnology and food sciences group.

Issues such as shelf life, quality decline and wastage renders the supply chain management of perishables “non conventional” and “challenging” says Kreft. In the Netherlands the loss of income per year is about €500million and equivalent to 5-10% of turnover.

In transit from producer to retailer, product quality can be affected by packaging, transport and logistics decisions – “and in the middle of it all is communicative packaging”, she said. “Monitoring sensors enable logistics decision-making. Variation in temperature leads to quality loss to waste and economic impact. Sensors provide a prediction tool, cut waste, save and make more money.”

In a trial, tomatoes were shipped by sea from Europe to the USA to test to what extent temperature monitoring could cut wastage and shrinkage, and by 4% was the answer.

In a cargo load of transport boxes worth €680,000 in total, breakeven point would be reached at a sensor unit cost of €0.31 per box.

In a second study a flexible “dynamic” expiry date ¬– as opposed to a conventional “defensive” expiry date – showed potential to cut food waste by 3% in meat packaging that carried a data logger designed to record decay. Temperature, relative humidity, gas conditions, bacteria levels were monitored and a “moving image” date was generated electronically. Assuming there was cooling system abuse, the date and price would change to tell the consumer “eat me!”

According to Hans van Grieken, a SustainPack presenter and vice-president of Capgemini – a Dutch innovation network which advises on strategies for future-looking management – to win business from economic benefits across the supply chain, providers of CP technology must be able first to communicate the return on investment, secondly, to identify the responsible party and, thirdly, who gains from any cut in losses.

The results of a pan-European study into attitudes to CP highlight that it will also be important to clarify the retailer position before deciding to add sensors to packaging. It revealed 50% of retailers do not want sensors on consumer packaging and 80% of retailers do not want consumers to be able to read sensors on packaging. Yet 100% of retailers want sensor technology for themselves and its distribution chain benefits, though none want to pay. Retailers apparently are afraid that the “dynamic” data could “confuse” the consumer and create “bad will” between the consumer and the brand owner or retailer.

It is still early days for CP, says the study leader Soren Ostergaard, head of packaging at the Danish Technological Institute. When looking at retailers’ “wait and see” attitude and their willingness to pay, Ostergaard says that at this stage it is important to note historical precedents of a technology such as the internet. Did we, for example, see back in 1985 the potential of the internet to take over our everyday lives, he asks? And how can you measure the value of communicative technologies and for that matter the internet?

Consumer focus groups in the Netherlands, Spain, Denmark and Slovakia gave their verdict on the concept of moving images and colour change in temperature loggers and flexible price/date codes. They approved of the 2-D barcode and mobile phone camera “readers” for revealing, for example, a wine’s full history and proof of brand authenticity. They also saw potential for alerts for allergy sufferers, expanding technical instructions to meet special needs of user groups and a spoken message to overcome visual impairment and so on.

The temperature logger was judged a good idea and “self-educating” in Denmark and Slovakia, while Dutch and Spanish groups thought the system “too complicated”.

Loopholes were also found in a flexible best-before date. It could lead to better food quality, but the cunning consumer would find ways to cheat the system. However, RH loggers in packs of sandwiches got the consumer green light.

So what is the science and technology that lie behind sensor development? Swedish research institute Acreo, of Norrköping, is looking to integrate organic and printed electronics for silicon-based temperature and RH loggers in sustainable packaging. It says it is crucial to future customer and consumer acceptability that all component parts and processes are considered harmless to the environment as well as to humans.

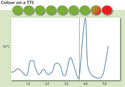

The monitoring sensor will apply electro-chromic/electro chemical technology explains Mats Robertsson, Acreo’s printed electronics senior scientist and a SustainPack project team leader. To produce dynamic displays readable by human eye, Acreo’s EC displays do not emit light; they change colour due to light absorption at different light wavelengths. This so-called electroluminescence is an optical and electrical phenomenon in which a material emits light in response to an electric current passed through it, or to a strong electric field. This is distinct from light emission which results from heat (incandescence) or the action of chemicals (chemo luminescence).

The technology combines transistors, switches and photo voltaics (solar power). Reversible switching of the EC component makes possible printed OLED (organic LED) displays for non-packaging uses as well as RFID tagging for track-and-trace and brand authentication purposes.

The printed electronics sector is predicted to grow 100% a year between 2004-2014 – by 2016, one trillion RFID tags could be in use – and Robertsson says industry needs a set of simple, early operational standards. Global packaging market trends analysis, in comparison, shows 3.5% annual growth to 2014. He believes a low-cost printed organic electronics temperature and RH logger of between €0.01and 1euro would be one obstacle cleared to gaining retailer acceptance, but there is already a lot of activity in the CP market.

As of now there is the accuracy, memory size, on and off switch and readout functionality to produce shelf display labels and smart product labels with display, push button and simple logics systems without detracting from the sustainability of the host packaging.

Printing machinery can already produce dry phase patterning (DPP) suitable for RFID antennae and EAS tags at extremely low cost and at fast speeds up to 150m/min (6,000m2/hr) on single layer or laminates from thin structures up to 50micron.

Indeed, printed electronics can currently be found in the market – Duracell’s disposable battery tester label from Avery Dennison sells in billions for a few cents per unit.

PolyIC’s printed polymer tag offers a self-adjusting “use before” date label at below 0.03 euro, while KSW Microtec and Infratab smart active labels combine printed batteries, electrochromic display and antenna. The electrochromic displays are sold in millions at about 0.05 eurocents per active square centimetre and the price could drop to 0.02-0.03 euro if sales increase to “tens of millions”, predicts industry analyst IDTechEx.

Cypak produced “the first paperboard computer” in 2004, but waiting in the wings is the Intellipak that will plant “electronics everywhere”. In this PacProject concept a cornflakes box electronically generates product information and on-pack games complete with press button keys, display, logics, battery and speaker,

Swedish paper and board company Stora Enso’s recently launched electrical delamination technology for “easy-open” packs. Controlled delamination materials (CDM) enable two attached packages or pack surfaces to separate easily. The claim is that in distribution solutions it could cut down material usage; an application of CDM can be envisaged in shelf-ready packaging, for example.

So strong is the drive forward “this technology has come to stay,” says Robertsson, although he adds “it will take some years before this area will take off.” However, the day will soon come when flexo print machinery will cheaply and easily apply to packaging similar anti-counterfeiting techniques based on magnetic pigments being used to produce magnetic signatures of banknotes. Christophe Barbier, research chemical engineer at Sweden’s Karlstadt University sees converter-enabled authentication systems helping to address the 5-7% of world trade made up of fake products.

All that is required are a reader, pigment, pattern and printability. Magnetic pigments can be added to normal flexo inks in up to 50-70% concentration without affecting flow properties. Printing inks containing variously 50%, 15% and 5% of magnetic pigment will build a usable code. If the supply chain does not want consumer-readable strategy, spot coating can hide the information, suggests Barbier.

Experiments so far have been on flat board with a one-dimensional code. The spacing between sensor and substrate is an important factor and could pose a challenge for corrugated board. A 2-D code would need several small sensors. “My belief is this technique is more suitable for labelling,” says Barbier.

According to VTT Technical Centre of Finland the possibilities for large-scale growth of identification labels and 2-D barcodes which use technologies that work in tandem with mobile phone cameras are immense. It has built systems for 2-D barcodes in information transfer, entertainment, anti-counterfeiting and logistics for packages. The use of colour gives a third dimension and potential for hidden codes in pictures.

Jali Heilmann, VTT’s senior research scientist, goes on to say packaging products will be one of “unlimited uses” for mobile phones. One billion of them will be sold around the world in 2007, of which 90% will have a digital camera. Information becomes readable with decoding software in the camera. And large amounts of information can be stored in small areas. Important consumer information can be made easily readable by eye while the rest of the information can be, in effect, hidden.

A 2-D barcode can even allow printed music to be picked up by mobile phone. While a cheeky use of the technology on a CD pack has seen would-be purchasers in Japan alerted to a cheaper internet offer.

Contact details

Acreo

www.acreo.se

Organic Electronics Association

www.oe-a.org

CONTACTS

Stora Enso

www.storaenso.com/cdm

PolyIC

www.polyic.com

Power Paper

www.powerpaper.com

VVT Technical Research Centre of Finland

www.vtt.fi

Cappgemini

www.capgemini.com

Wageningen University and Research Centre

www.wur.nl/UK/

Danish Technological Institute

www.danishtechnology.dk/

Karlstadt University

www.kau.se/eng/